Setting up a soy milk and paneer processing unit involves several steps, from sourcing raw materials to processing, packaging, and quality control. Here’s an overview of the processes and technologies involved:

- Raw Material Sourcing:

- Soybeans: The primary raw material for soy milk production is soybeans. These should be sourced in bulk and inspected for quality.

- Cleaning and Sorting:

- The soybeans need to be cleaned and sorted to remove impurities such as stones, debris, and damaged beans.

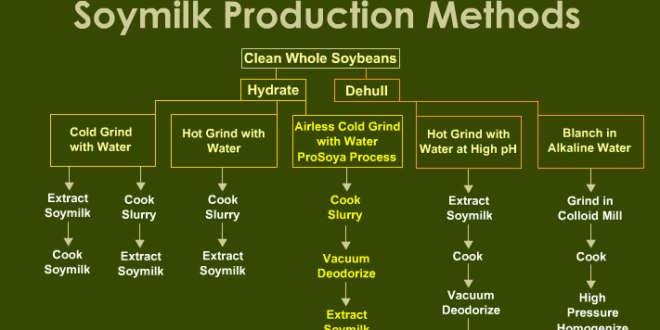

- Soaking and Dehulling:

- Soybeans are soaked in water to soften them and facilitate dehulling.

- Dehulling machines remove the outer husk of the soybeans.

- Grinding:

- The dehulled soybeans are ground into a fine paste using industrial grinders.

- The consistency of the paste can be adjusted depending on the desired final product.

- Heating and Enzyme Inactivation:

- The soybean paste is heated to deactivate enzymes that can cause off-flavors and spoilage.

- This step also helps in improving the flavor and texture of the soy milk.

- Separation:

- The heated soybean paste is separated into soy milk and okara (the insoluble residue) using a centrifuge or filter press.

- Cooking and Flavoring:

- The soy milk is cooked to enhance its flavor and ensure safety.

- Flavorings such as sugar, salt, and vanilla can be added at this stage to create different variants.

- Homogenization:

- The soy milk is passed through a homogenizer to break down fat globules and ensure uniform consistency.

- Pasteurization:

- The soy milk is pasteurized to kill any remaining bacteria and increase shelf life.

- Packaging:

- The pasteurized soy milk is packaged in sterilized containers, typically Tetra Paks or plastic bottles.

- Quality Control:

- Quality control measures include checking for consistency, taste, microbial contamination, and package integrity.

- Paneer Production:

- Paneer is made from milk. You would need to source fresh milk or set up a milk processing unit alongside your soy milk processing unit.

- The milk is boiled, and an acidifying agent like lemon juice or vinegar is added to curdle the milk.

- The curdled milk is strained to separate the whey from the curd, which is the paneer.

- The paneer is then pressed to remove excess moisture and shaped into blocks or cubes.

- Packaging:

- Paneer is typically packaged in airtight containers to maintain freshness.

Technologies and Equipment Involved:

- Grinders: Industrial-grade grinders are used for grinding soybeans into a paste.

- Heating Equipment: Steam cookers or direct steam injection systems are used for heating soybean paste.

- Separation Equipment: Centrifuges and filter presses are used to separate soy milk from okara.

- Homogenizer: Homogenizers ensure uniform consistency in soy milk.

- Pasteurization Equipment: Pasteurization can be achieved through various methods, including plate heat exchangers or tubular pasteurizers.

- Packaging Machinery: Automatic filling and sealing machines are used for packaging soy milk and paneer.

- Quality Control Tools: Lab equipment for testing quality and safety, including pH meters, microbial analysis tools, and sensory evaluation.

- Paneer Press: A paneer press is used to press and shape the paneer blocks.

- Storage and Refrigeration: Adequate storage facilities, including refrigeration for both soy milk and paneer, are crucial for maintaining product quality.

- Cleaning and Sanitization Equipment: Industrial washing and sanitization equipment to maintain hygiene standards in the processing unit.

It’s essential to comply with food safety and quality standards, follow local regulations, and invest in modern, efficient equipment to ensure the success of your soy milk and paneer processing unit. Additionally, consider factors like marketing, distribution, and branding to build a successful business in this industry.

more info – info@soyafood-in

SoyaFood A Golden Bean Food Product…

SoyaFood A Golden Bean Food Product…