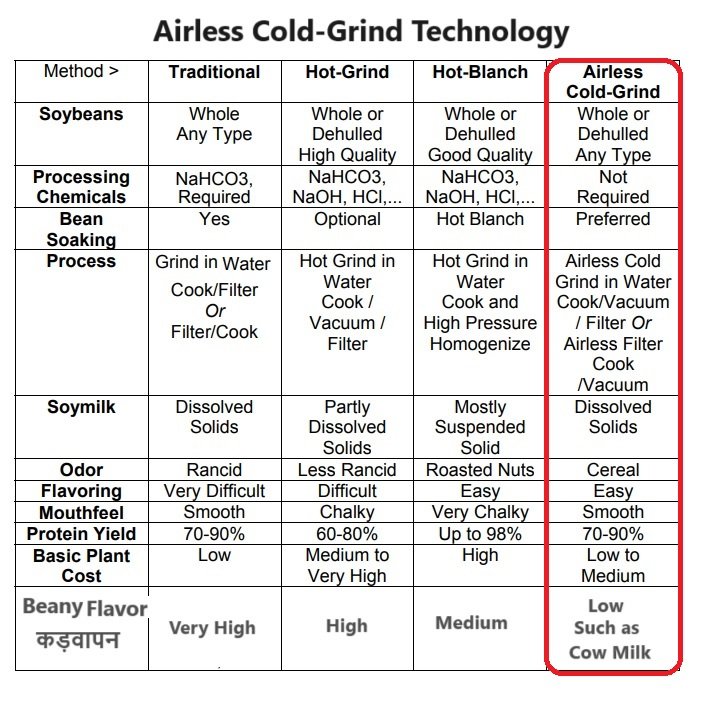

Airless cold grinding technology for soy milk is an innovative method of producing soy milk without using heat during the grinding process. This technology is designed to preserve the natural flavors and nutrients of soybeans, resulting in a fresher and more vibrant soy milk. Here’s a detailed explanation of this process:

1. Introduction to Airless Cold Grinding:

- Airless cold grinding is a process that utilizes special equipment and techniques to grind soybeans into milk without applying heat.

- Traditional soy milk production involves heating the soybean paste during grinding, which can lead to flavor and nutrient loss. Airless cold grinding aims to overcome these issues.

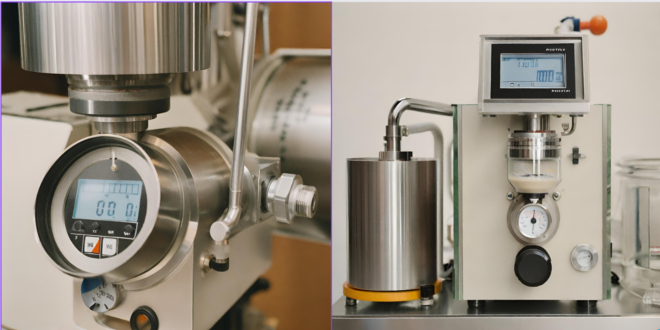

2. Equipment Used:

- Airless Grinding Machine: This is the central piece of equipment in this process. It’s designed to grind soybeans without introducing heat or oxygen.

- Storage Tanks: Soybeans and water are stored separately in tanks before being introduced to the grinding machine.

- Filters: After grinding, the soy milk is typically passed through filters to remove any remaining solids or particles.

3. The Airless Cold Grinding Process:

- The process begins by soaking and dehulling soybeans as in traditional soy milk production.

- Instead of heating, the soybeans are introduced to the airless grinding machine in their raw state.

- The grinding machine uses special technology to break down the soybeans into a fine paste without generating heat.

- Water is added gradually to the soybean paste during the grinding process to create a smooth milk-like consistency.

- The soy milk produced using this method is never subjected to high temperatures, preserving its natural taste and nutritional value.

4. Benefits of Airless Cold Grinding:

- Better Flavor and Aroma: The absence of heat in the grinding process helps retain the natural, fresh flavor and aroma of soybeans.

- Preservation of Nutrients: Nutrients, such as vitamins, minerals, and proteins, are better preserved since they are not exposed to high temperatures.

- Extended Shelf Life: Airless cold grinding can result in soy milk with an extended shelf life compared to traditional methods because it is less prone to spoilage.

- Improved Texture: The soy milk produced using this method often has a smoother texture.

5. Applications:

- Airless cold grinding technology can be applied not only to soy milk but also to other plant-based milks, such as almond milk or oat milk, to preserve their natural characteristics.

6. Challenges:

- Implementing airless cold grinding technology may require specialized equipment and processes, which can be costly to set up initially.

- Production capacity may be limited compared to traditional methods, making it more suitable for smaller-scale or artisanal operations.

7. Market Potential:

- The demand for minimally processed and nutritionally rich plant-based milk alternatives has been growing steadily, making airless cold grinding technology an attractive option for producers aiming to meet this demand.

Airless cold grinding technology is an exciting development in the plant-based milk industry, offering a way to produce high-quality soy milk that retains its natural flavors and nutritional benefits. While it may require initial investment and specialized equipment, it has the potential to appeal to consumers seeking premium, minimally processed plant-based milk products.

SoyaFood A Golden Bean Food Product…

SoyaFood A Golden Bean Food Product…